Get your cutting tools resharpened and re-coated for less than half the cost of new tooling, yet enjoy performance at least 90% as good. On top of that, we typically turn tools around in two weeks. How?

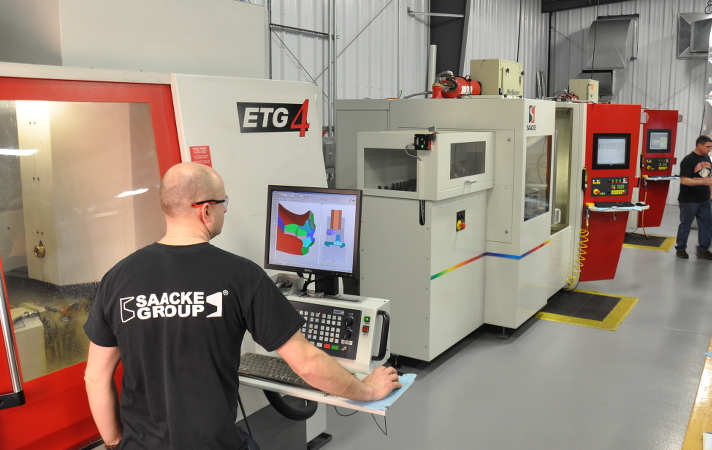

- State-of-the art CNC tool grinders running a variety of software, including NUMROTO and WALTER Helitronic Tool Studio

- Experienced technicians that understand modern tool geometries and how to grind them. That includes high tech drill points, variable helix endmills with unequal indexing, sophisticated step tools, and more. You won’t stump us!

- Modern CNC measuring machines and support equipment, including OD grinders for tools that require a smaller neck after regrinding

- In-house PVD coating for titanium nitride (TiN), titanium aluminum nitride (TiAlN) and aluminum titanium nitride (AlTiN). We’ll re-coat with the same coating you had before to optimize adhesion

- In-house edge preparation (i.e. hone), a black art that helps achieve optimum performance

Cut your cutting tool costs now and send us your regrinds! We guarantee your reconditioned tools will perform at least 90% as well as new tools.